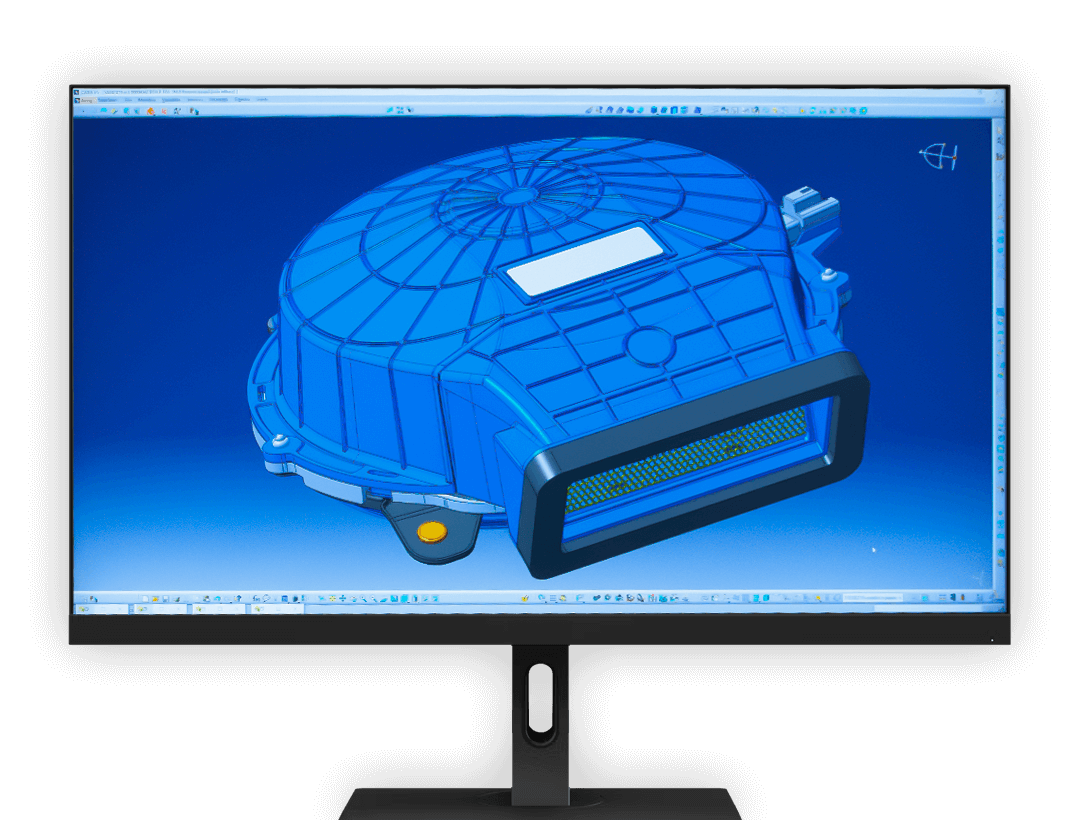

"The development process of a loudspeaker involves several stages, starting from design to final production."

We employ cutting-edge techniques and technologies at every stage of the process, with the aim of ensuring precision and innovation. We are constantly seeking solutions that allow us to improve and respond better to customer needs, always striving to combine experience with new tools to deliver quality results. Innovation is a priority for us, and we are committed to maintaining this spirit of continuous improvement in everything we do.